Material and Strength of Trasteel Teeth for Excavators

Material and strength of excavator teeth are key factors to ensure optimal performance in demanding jobs. Trasteel, as a market leader, uses high-quality steel to provide durable and efficient teeth for all types of terrain.

What material ensures the strength of excavator teeth?

Excavator teeth are subjected to extreme working conditions, which require the use of top-grade materials. At Trasteel, we use special steel with an optimized composition that includes carbon, chromium, and nickel, elements that maximize resistance and durability.

Thus, our teeth meet the most demanding standards, offering an excellent balance between toughness and wear resistance.

Main features of Trasteel excavator teeth

As one of the leading excavator tooth manufacturers, Trasteel focuses on offering high-quality products that guarantee maximum efficiency and durability in any application.

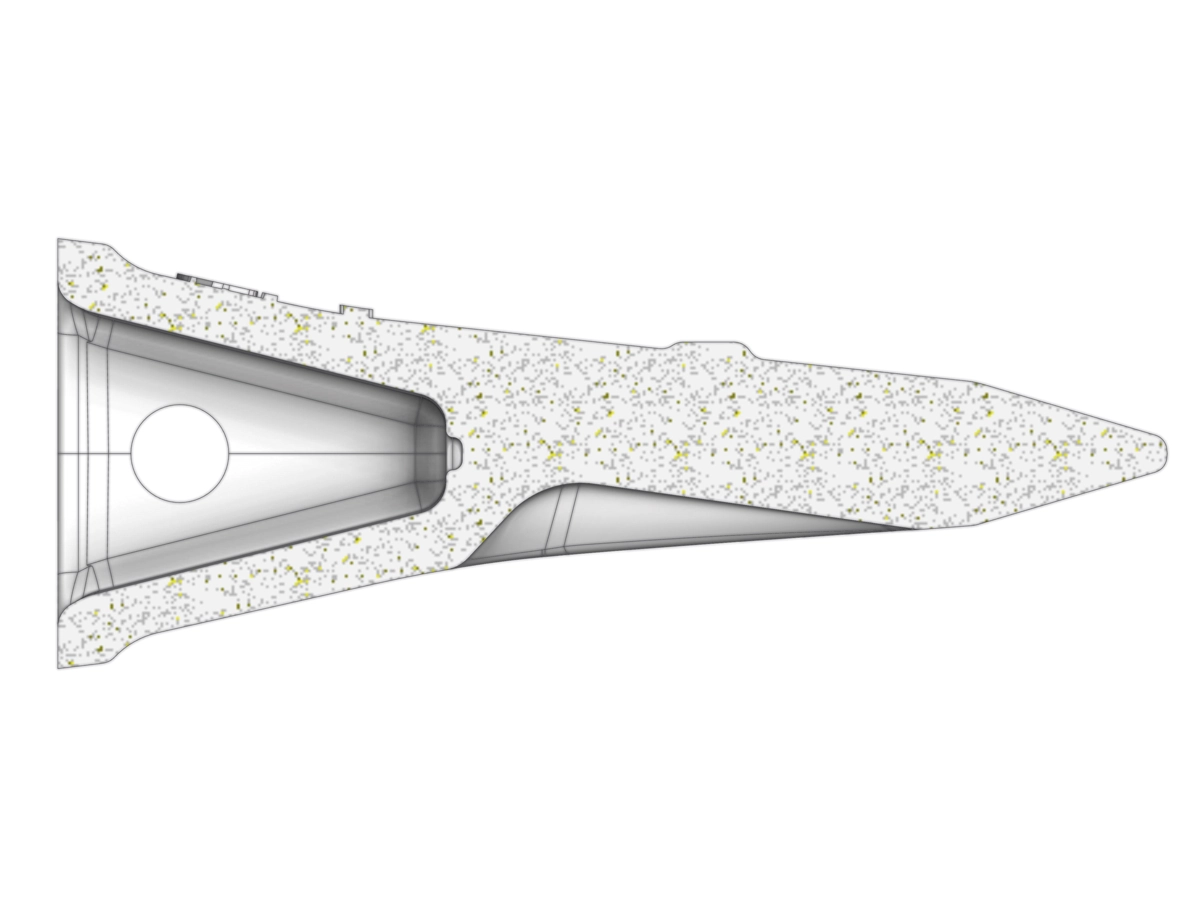

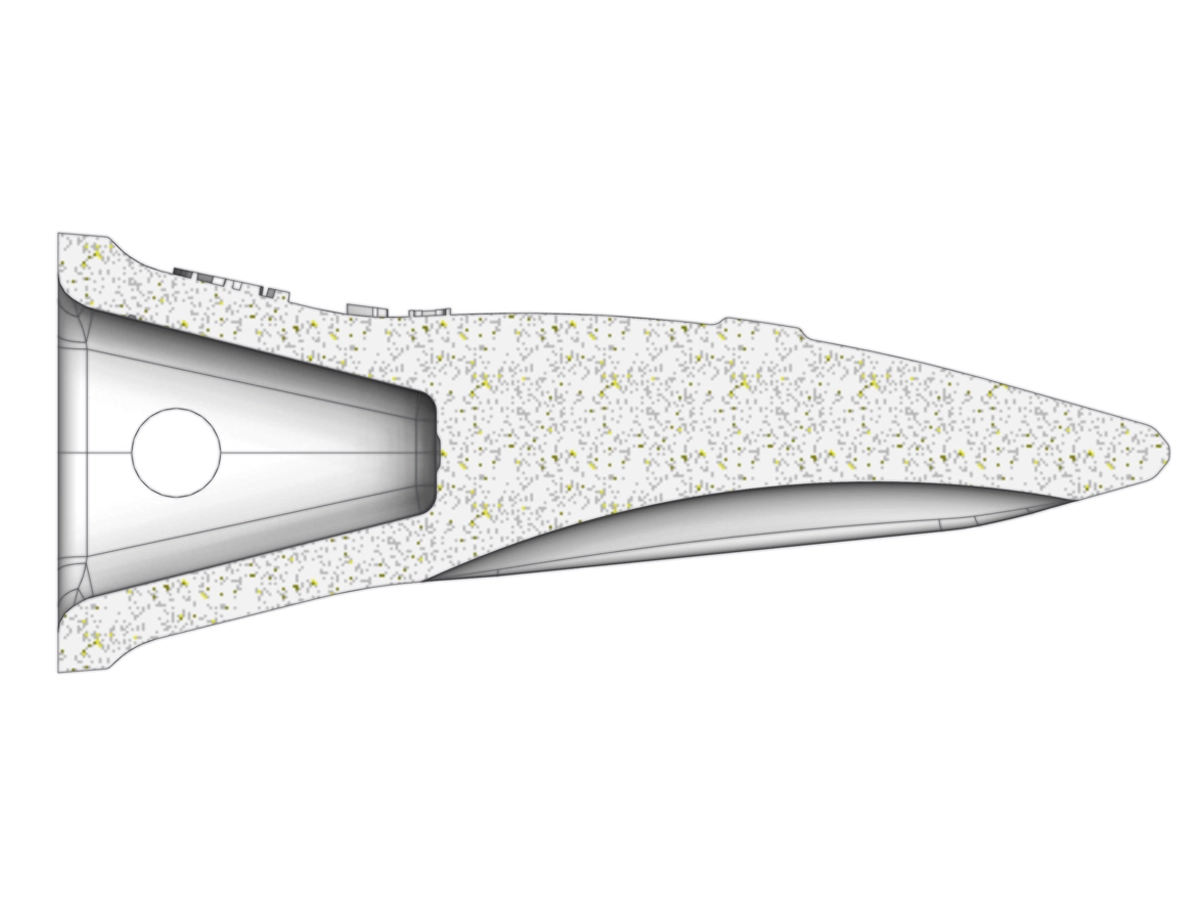

Trasteel teeth are designed with a focus on maximum operational efficiency. Every detail in their composition and manufacturing ensures superior performance in demanding environments, extending machinery life and optimizing operating costs.

- Wear resistance: Designed to withstand abrasive conditions and extend equipment life.

- Advanced chemical composition: High-purity steel with low levels of impurities such as phosphorus and sulfur.

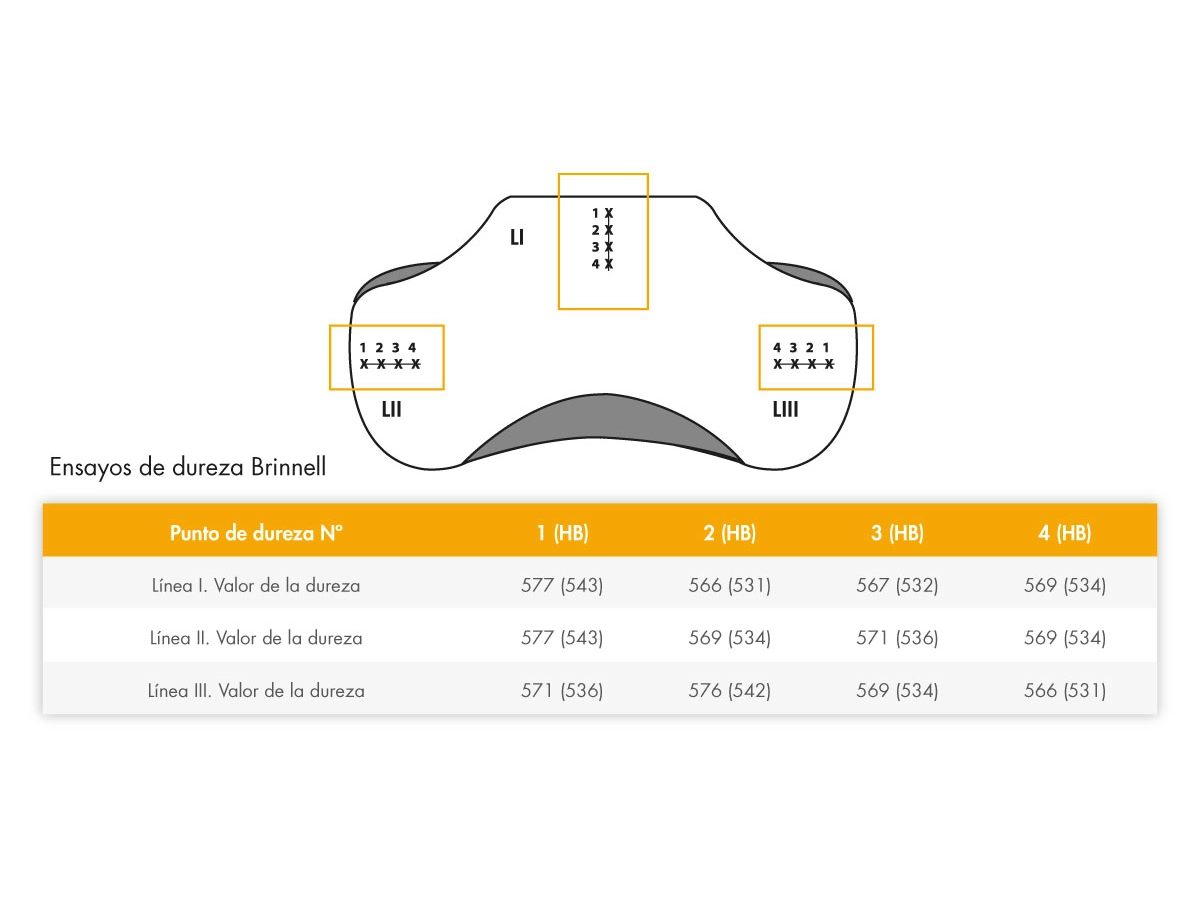

- Optimal hardness: With Vickers hardness values between 566–577 HV and equivalent to 532–543 HB.

- Universal compatibility: Adaptable to systems from leading brands like Caterpillar, Komatsu, JCB, and Liebherr.

Thanks to these features, Trasteel teeth not only optimize machinery performance but also reduce operating costs by minimizing wear and extending maintenance intervals.

The best steel type for excavator teeth

Each type of steel used in the manufacture of our excavator teeth is carefully selected to ensure optimal performance across various applications. From earthmoving in construction to intensive mining operations, Trasteel offers a solution for every need:

- TST10 and TST30 steel: Ideal for construction teeth, with hardness ranges between 47–53 HRC.

- TST20: Recommended for heavy-duty construction work, with impact values over 22J.

- TST40: Specifically designed for mining applications with maximum durability and resistance.

Advantages of choosing Trasteel

At Trasteel, we not only offer information about excavator teeth but also solutions that exceed our clients’ expectations. The combination of advanced technology, innovative design, and high-quality materials positions us as leaders in the wear material sector.

Discover more

Check our excavator teeth catalog to explore all available options and optimize your equipment’s performance. Trasteel, always one step ahead!